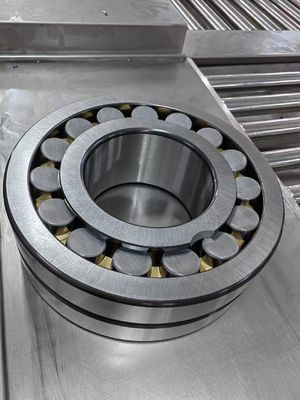

22319CA/W33

Product Description:

The 22319CA/W33 is a spherical roller bearing designed to handle heavy radial loads along with moderate axial loads. The "CA" designation indicates that it features a reinforced solid brass cage, which provides enhanced impact resistance and stability, making it suitable for heavy-duty machinery. The "W33" indicates that the bearing has a lubrication groove and three lubrication holes on the outer ring, facilitating effective lubrication distribution and extending bearing life. This bearing is ideal for applications in vibrating environments, such as mining equipment, rolling mills, and large gearboxes.

Structure

Spherical roller bearings with tapered bore bore with the rear code K and K30 installed on the matching adapter sleeve become rear code K+H type and K30+H type bearings. These bearings can be mounted on a smooth shaft without a shoulder and are suitable for applications where the bearing needs to be mounted and dismounted frequently. In order to improve the lubrication performance of the bearing, there are annular oil grooves in the outer ring of the bearing and three evenly distributed oil holes are drilled, the post-code is W33.

Raw Material & Structure

| Part No. |

Components |

Raw Material |

Dimension/mm |

Rated Load/KN |

Weight |

| Cor |

Cr |

|

22319CA/ W33

|

Outer Ring |

Gcr15/G20CrNi2MoA |

95x200x67 |

614 |

789 |

10.4

kg

|

| Inner Ring |

Gcr15/G20CrNi2MoA |

| Roller |

Gcr15/G20CrNi2MoA |

| Cage |

Steel/Brass/Polyamide |

| Retainer |

|

| Space Ring |

|

Advantages

1. The radial load capacity is large. Easy to install, can be installed directly or use the tight sleeve, assembly cylinder installed on the cylindrical shaft.

2. Can bear a certain axial load. The outer ring raceway of this kind of bearing is spherical and can bear large radial load. Therefore, it has the aligning performance, which is not affected by the misalignment of shaft and bearing box or shaft deformation and deflection, and can compensate the coaxiality error.

3. With two rows of spherical rollers, the outer ring has a common concave spherical raceway, the inner ring has two concave raceway inclined to an Angle with the bearing axis, the center of curvature of the outer ring raceway is consistent with the bearing center.

4. In addition to bear radial load, but also can bear two-way axial load and its combined load. The bearing capacity is large, and it has good vibration resistance and impact resistance.

Scope of application

Widely used in papermaking machinery, reducers, railway vehicle axles, rolling mill gearbox bearing housing, rolling mill rolls, crushers, vibrating screens, printing machinery, woodworking machinery, various industrial reducers and other industries.

How to Install Spherical Roller Bearing?

Universal Failure Modes

1. The bearing is damaged when the aligning Angle is exceeded during installation.

2. When installing the bearing inner ring with the press, avoid the support under the outer ring to prevent the installation of the bearing when the bearing is pressed down, resulting in the crushing of the outer ring edge.

3. The installation axial was preloaded which causes damage to the aligning roller bearing.

4. Fracture of inner ring caused by large installation interference.

5. Poor lubrication leads to early wear of bearing raceway.

JATEC Internal control size chart

| Items(Um) |

Outer ring |

Inner ring |

Rollers |

|

Datum end face flatness

Double-ended parallelism

|

≤0.003

≤0.003

|

≤0.002

≤0.003

|

≤0.001

≤0.001

|

| Datum end face roughness |

≤0.32 |

≤0.32 |

≤0.32 |

| Outer ovality/roundness |

≤0.003/≤0.003 |

≤0.003/≤0.002 |

≤0.002 |

| Raceway ovality/roundness |

≤0.003/≤0.003 |

≤0.003/≤0.002 |

|

| Inner hole ovality/taper |

≤0.003/≤0.003 |

≤0.003/≤0.002 |

|

| Raceway milling/super roughness |

≤0.32/0.08 |

≤0.32/0.032 |

≤0.025 |

| Size scattering |

≤0.01 |

≤0.01 |

≤0.002 |

| Tertiary/quadratic detection |

≤0.0001 |

≤0.0001 |

≤0.0001 |

| Full inspection of surface quality |

Eddy current flaw detection |

Eddy current flaw detection |

Eddy current flaw detection |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!